Entryway Bench wood plans

Entryway Bench Woodworking Plans

Skill level: Beginning woodworker

Time to complete: 1-2 weekends, including painting

Estimated cost: $200-$300 for one bench, one shelf, and table

Materials

49x97-inch sheet of 3/4-inch medium-density fiberboard (MDF)

Wood glue

One package 6d finishing nails

Six No. 6x1-1/4-inch drywall screws

Six No. 8x2-inch drywall screws

Four wood bun feet*

Two wood legs*

Two lengths wood molding*

Wood filler

1 quart latex primer and semigloss enamel paint

Three coat hooks for wall shelf

Items #02007081 (fluted tulip bun foot)

#02005568 (fluted dining table leg)

#0200092 (Hardwood scroll)

Van Dyke's Restorers www.vandykes.com

Tools

Tape rule

Pencil

Angle square or combination square

C-clamps

Table saw (with standard and dado blades)

Jigsaw

Sanding block with 100-grit sandpaper

Drill

Drill bits (1/16, 3/16 with countersink)

No. 2 Phillips screwdriver (or driver bit for drill)

Hammer

Nail set

Putty knife

Paintbrushes

Stud finder

Builder's level

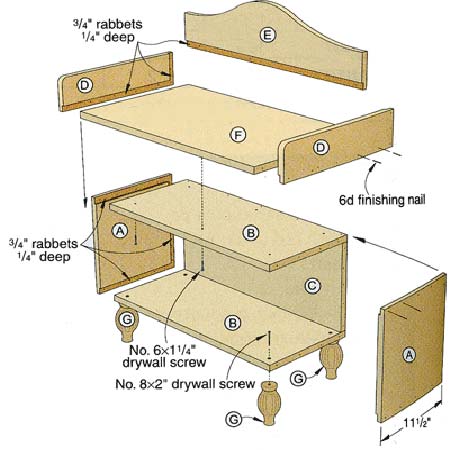

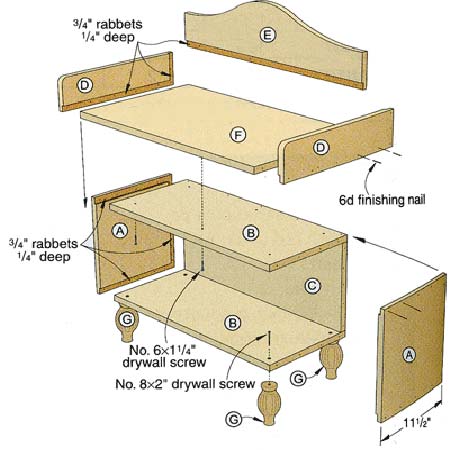

Use the table saw to cut the individual parts (A-F) from MDF. Next, fit the table saw with a 3/4-inch dado blade (or use a router with a 3/4-inch straight bit) to cut the rabbets on parts A, D, and E as shown. These joints create stronger corners and make assembly easier; cut them on the upper, lower, and rear edges of the box ends (A), the lower and rear edges of the seat end rails (D), and the lower edge of the seat crest rail (E); make sure rabbets are on the inside face of the pieces.

Next, use a pencil to trace the desired curve on the seat crest rail (E); the exact contour isn't critical, but keep it symmetrical and make sure the ends taper to 4 inches wide to align with the seat end rails (D). Use the jigsaw to cut along the line and also to cut a small radius on the upper front corners of the end rails as shown; sand curves smooth.

Assembly

1. Start by assembling the box portion of the bench. First, drill 1/16-inch holes (for nailing) along the rabbets and other areas that will abut the edge of an adjoining piece. Secure the rabbeted lower edges of the box ends (A) to the edges of the bottom panel (B) with glue and 6d finishing nails, making sure front edges are flush at the corners; repeat to attach the top panel (B). Next, use glue and nails to attach the box back panel as shown.

2. Use the same glue-and-nails technique to assemble the seat ends (D) and crest rail (E) to the seat panel (F) as shown. Then drill six 3/16-inch holes through the box top panel (one hole at each corner, and two near the center); fit the seat assembly atop the bench box, adjust for a 2-1/2-inch front overhang and 3/4-inch overhang on each end, then drive 1-1/4-inch drywall screws up through the box panel to secure the seat.

3. Lay the bench on its back and drill a 3/16-inch hole 2 inches in from each corner in the bottom panel; use the 2-inch drywall screws to attach the bun feet (G). Set the bench upright, use a nail set to countersink the finishing nails, and fill holes with wood filler. Use the sanding block to ease sharp edges and corners, then set the bench aside for painting.

Time to complete: 1-2 weekends, including painting

Estimated cost: $200-$300 for one bench, one shelf, and table

Parts |

[A] Ends |

[B] Top/Bottom |

[C] Rear |

[D] End Rails |

[E] Crest Rail |

[F] Seat Panel |

Thickness |

3/4 |

3/4 |

3/4 |

3/4 |

3/4 |

3/4 |

Width |

11-1/2 |

11-1/2 |

10 |

4 |

7 |

15-1/2 |

Length |

12-1/4 |

25 |

25 |

15 |

26-1/2 |

26-1/2 |

Quantity |

2 |

2 |

1 |

2 |

1 |

1 |

Note: All dimensions are in inches. See materials list for bun feet specifications |

||||||

Materials

49x97-inch sheet of 3/4-inch medium-density fiberboard (MDF)

Wood glue

One package 6d finishing nails

Six No. 6x1-1/4-inch drywall screws

Six No. 8x2-inch drywall screws

Four wood bun feet*

Two wood legs*

Two lengths wood molding*

Wood filler

1 quart latex primer and semigloss enamel paint

Three coat hooks for wall shelf

Items #02007081 (fluted tulip bun foot)

#02005568 (fluted dining table leg)

#0200092 (Hardwood scroll)

Van Dyke's Restorers www.vandykes.com

Tools

Tape rule

Pencil

Angle square or combination square

C-clamps

Table saw (with standard and dado blades)

Jigsaw

Sanding block with 100-grit sandpaper

Drill

Drill bits (1/16, 3/16 with countersink)

No. 2 Phillips screwdriver (or driver bit for drill)

Hammer

Nail set

Putty knife

Paintbrushes

Stud finder

Builder's level

Use the table saw to cut the individual parts (A-F) from MDF. Next, fit the table saw with a 3/4-inch dado blade (or use a router with a 3/4-inch straight bit) to cut the rabbets on parts A, D, and E as shown. These joints create stronger corners and make assembly easier; cut them on the upper, lower, and rear edges of the box ends (A), the lower and rear edges of the seat end rails (D), and the lower edge of the seat crest rail (E); make sure rabbets are on the inside face of the pieces.

Next, use a pencil to trace the desired curve on the seat crest rail (E); the exact contour isn't critical, but keep it symmetrical and make sure the ends taper to 4 inches wide to align with the seat end rails (D). Use the jigsaw to cut along the line and also to cut a small radius on the upper front corners of the end rails as shown; sand curves smooth.

Assembly

1. Start by assembling the box portion of the bench. First, drill 1/16-inch holes (for nailing) along the rabbets and other areas that will abut the edge of an adjoining piece. Secure the rabbeted lower edges of the box ends (A) to the edges of the bottom panel (B) with glue and 6d finishing nails, making sure front edges are flush at the corners; repeat to attach the top panel (B). Next, use glue and nails to attach the box back panel as shown.

2. Use the same glue-and-nails technique to assemble the seat ends (D) and crest rail (E) to the seat panel (F) as shown. Then drill six 3/16-inch holes through the box top panel (one hole at each corner, and two near the center); fit the seat assembly atop the bench box, adjust for a 2-1/2-inch front overhang and 3/4-inch overhang on each end, then drive 1-1/4-inch drywall screws up through the box panel to secure the seat.

3. Lay the bench on its back and drill a 3/16-inch hole 2 inches in from each corner in the bottom panel; use the 2-inch drywall screws to attach the bun feet (G). Set the bench upright, use a nail set to countersink the finishing nails, and fill holes with wood filler. Use the sanding block to ease sharp edges and corners, then set the bench aside for painting.